51.2V 150Ah LiFePO4 PowerWall Lithium Ion Battery

Brand : EnrSaver

Product origin : China

Delivery time : 7-15day

Supply capacity : 10000 Pcs/Day

◆51.2V 150Ah Wall Mounted LiFePO4 Battery, safety, deep cycle and long lifespan.

◆LCD monitor the energy storage power data and operating status.

◆Air cooling to improve the reliability of the product.

◆External main switch to reduce product power consumption and improve safety.

◆Wall brackets, which can meet the installation and use of different place.

◆BMS bulit inside, over-voltage, over-load, over-temperature protection, atc.

◆Compatible, can be connected to different types of loads within the voltage range.

Download

1. Scope

The specification shall be applied to LiFePO4 rechargeable battery pack Of 24140160-16S3P which is manufactured by Foshan EnrSaver New Energy Technology Co., Ltd.

2. Main specifications

2.1 Cell Battery specifications

Lithium Battery Cell | No. | Item | General Parameter | Remark | |

1 |

Rated Capacity | Typical | 50Ah | Standard discharge (0.2C5A) after Standard charge | |

Minimum | 50Ah | ||||

2 | Nominal Voltage | 3.2V | Mean Operation Voltage | ||

3 |

Internal Impedance |

≤0.65 mΩ | Internal resistance measured at AC 1KHZ after 50% charge The measure must uses the new batteries that within one week after shipment and cycles less than 5 times | ||

4 |

Dimension | Thickness:Max 24.5mm |

Initial Dimension | ||

Width:Max 140.5mm | |||||

Height:Max 160.5mm | |||||

5 | Weight | 1. 15kg | APPROX | ||

6 |

Standard charge | Constant Current 0.33C5A Constant Voltage 3.65V 0.02C5A cut-off |

Charge time : Approx3.5h | ||

7 |

Rapid Charge | Constant Current 1C5A Constant Voltage 3.65V 0.01C5A cut-off | Charge time : Approx1.5h@≧10C | ||

8 | Standard discharge | Constant current 0.33C5A end voltage 2.5 V |

16.5A | ||

9 | Maximum discharge current | Constant current:2C5A end voltage :2.5 V |

100A@≧0C | ||

10 | Volumetric specific energy |

295 WH/L |

APPROX | ||

11 | Gravimetric specific energy | 139WH/KG | APPROX | ||

2.2 Battery Pack specifications

Lithium Battery Package | No. | Item | General Parameter | Remark | |

1 | Combination method | 16S3P | |||

2 |

Rated Capacity | Typical | 150Ah | Standard discharge after Standard charge (package) | |

Minimum | 147Ah | ||||

3 | Factory Voltage | 51V-53V(40-60%) | Mean Operation Voltage | ||

4 | Voltage at end of Discharge |

40-44V |

Discharge Cut-off Voltage | ||

5 | Charging Voltage | 56-58V | |||

6 |

Internal Impedance |

≤60mΩ | Internal resistance measured at AC 1KHZ after 50% charge The measure must uses the new batteries that within one week after shipment and cycles less than 5 times | ||

7 |

Standard charge | Constant Current30A Constant Voltage see No.5 0.02CA cut-off |

Charge time : Approx 6 h | ||

Limiting current | 20A | ||||

8 |

Standard discharge | Constant current:30A end voltage see NO.4 | |||

9 | Maximum Continuous Charge Current |

100A |

T≥10ºC | ||

10 | Maximum Continuous Discharge Current |

100A | T≥10ºC | ||

11 | Operation Temperature Range | Charge: 0~45C | 60±25%R.H. Bare Cell | ||

Discharge: -20~55C | |||||

12 |

Storage Temperature Range | Less than 12 months : - 10~35C |

60±25%R.H. at the shipment state | ||

less than 3 months: - 10~45C | |||||

Less than 7 day : -20~65C | |||||

13 | Dimensions | 680*485*180 (220)mm | Include Bracket | ||

14 | Weight | Approx :87kg | |||

3. Battery Management System Specification

3.1 BMS function introduction

1): The BMS is designed for 15/16 series lithium battery.

2): The BMS have all functions which are :

overcharge detection function

over discharge detection function)

over current detection function

short detection function

Temperature detection function

balance function

communicate function

Alarm function

Total capacity function

Storage history function

3.2 BMS Protect parameter

Items | Details | Standard |

Cell overcharge protection | Overcharge detection voltage | 3.65± 0.025V |

Overcharge detection delay time | Typical:1.0s | |

Overcharge release voltage | 3.38± 0.02V | |

Cell over-discharge protection | Over-discharge detection voltage | 2.5± 0.02V |

Over-discharge detection delay time | Typical:1.0s | |

Over-discharge release voltage | 2.9± 0.02V or charge release | |

Over-current protection | discharge Over-current protection current1 | 130± 10A |

discharge Over-current detection delay time 1 | 1S | |

discharge Over-current protection current 2 | 150± 10A | |

discharge Over-current detection delay time 2 | ≤100m±50ms | |

Charge OC protection current | 130± 10A | |

Short protection | Short protection current | 350± 10A |

Protection condition | Load short | |

Detection delay time | ≤300us | |

Protection release condition | Charging release | |

Temperature(T) protection | Charge high T protection | 55± 3C |

Charge high T recover | 50± 5C | |

Discharge high T protection | 65± 5C | |

Discharge high T recover | 60± 5C | |

Charge low T protection | -5± 5C | |

Charge low T recover | 0± 5C | |

Discharge low T protection | -20± 5C |

Discharge low T recover | -15± 5C | |

Balance | Balance threshold voltage | 3.45V |

Communication | It has RS232 /RS485 and canbus standard communication interface, it can real-time monitoring the capacity of battery bank, the voltage, current, environment temperature, and charging/discharging current. | |

Alarm | It has over-temperature, over charge, under-voltage, over-current, short circuit alarm Function. | |

4. Appearance and structural dimensions

There shall be no such defect as scratch, bur and other mechanical scratch, and the connector should be no rust dirt. The structure and dimensions see attached drawing of the battery

Unit (mm) | |||||

Total Length | 680 | Width | 485 | Height | 180 |

Length outside | / | WIRE | / | Terminals | 8mm fast plug |

Remarks | Output Cable: 35mm2,length 2m | ||||

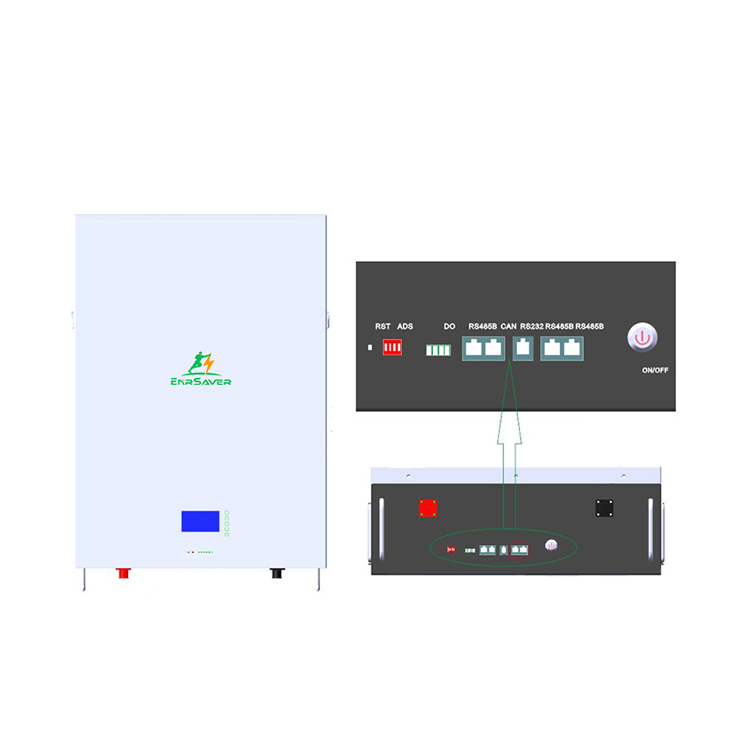

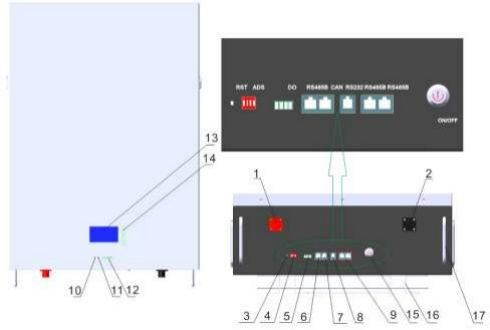

5. Case Structure of Battery Pack

Described as followed

No. | Description | Silk-screen | Remark |

1 | UES0600 | P+ P+ | Output terminal |

2 | UES0600 | P- P- | Output terminal |

3 | port Reset button | RST | For reset the batter |

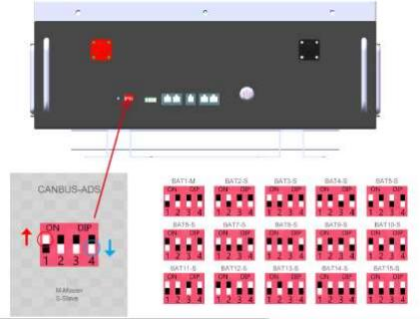

4 | Dial switch | ADS | Set the address |

5 | Do | ||

6 | CANbus Port | CANbus | CANbus and inverter connection port |

7 | RS485A Port | RS485 | RS485 and inverter connection port |

8 | RS232 Port | RS232 | RS232 communication port |

9 | RS485B port | RS485 | RS485 parallel communication interface |

10 | LED | RUN | Operation indicator |

11 | LED | ALM | Alarm indicator |

12 | LED | CAPACITY | Capacity indicator |

13 | LCD | ||

14 | LCD Key | ||

15 | Switch | ||

16 | Bracket | ||

17 | Handle |

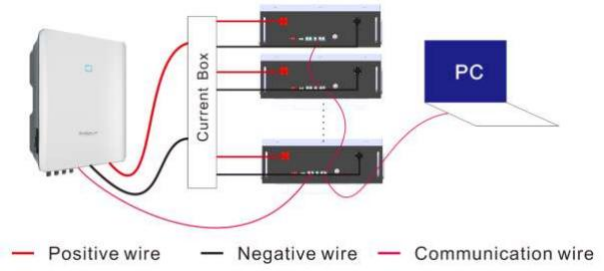

6. Connection mode for parallel communication

6.1 RS485 Parallel Communication

While in RS485 parallel communication, dial-up addresses of battery module are 1,2,3,4……14,15; By this method, we can be allowed to read each data depending on battery module. Any battery other than address 0 can be connected to the host computer; FF polling mode used as consulting mode.

Note: RS485 communication address can not be 0, the address set by the host computer is required to be the same as the battery communication address, do not have duplicate addresses, otherwise communication may be affected.

6.2 Address Switch function (Only in Parallel)

7. Battery test equipment

7.1 Dimension Measuring Instrument

The dimension measurement shall be implemented by instruments with equal or more precision scale of 0.1mm.

7.2 Voltmeter

Standard class specified in the national standard or more sensitive class having inner impedance not less than 10 KΩ/V.

7.3 Ammeter

Standard class specified in the national standard or more sensitive class. Total external resistance including ammeter and wire is less than 0.01Ω .

7.4 Impedance Meter

Impedance shall be measured by a sinusoidal alternating current method(AC 1kHz LCR meter).

8. Standard Test Condition

Test should be conducted with new batteries within one month after shipment from our factory and the cells shall not be cycled more than five times before the test. Unless otherwise defined, test and measurement shall be done under temperature of 23±2C and relative humidity of less

75%.,air 86Kpa~106Kpa.

Unless otherwise defined, 30min,rest period after charge,30min,rest period after discharge.

Handling Precautions and Guideline

For Li-ion Rechargeable Batteries

Preface

This document of 'Handling Precautions and Guideline Li-ion Rechargeable Batteries' shall be applied to the battery cells manufactured by EnrSaver

Note (1) :

The customer is requested to contact Foshan EnrSaver New Energy Technology Co., Ltd. in advance, if and when the customer needs other applications or operating conditions than those described in this document. Additional experimentation may be required to verify performance and

safety under such conditions.

Note (2) :

Foshan EnrSaver New Energy Technology Co., Ltd. is not responsible for any accidents

caused by using the battery under conditions other than those specified in this specification.

Note (3):

Foshan EnrSaver New Energy Technology Co., Ltd. will inform, in a written form, the customer of improvement(s) regarding proper use and handling of the cell, if it is deemed necessary.

Danger!

— Do not immerse the battery in water or allow it to get wet.

— Do not use or store the battery near sources of heat such as a fire or heater.

— Do not use any chargers other than those recommended by ENRSAVER.

— Do not reverse the positive(+) and negative(-) terminals.

— Do not connect the battery directly to wall outlets or car cigarette-lighter sockets.

— Do not put the battery into a fire or apply direct heat to it.

— Do not short-circuit the battery by connecting wires or other metal objects to the positive(+)

and negative(-) terminals.

— Do not pierce the battery casing with a nail or other sharp object, break it open with a hammer,

or step on it.

— Do not strike, throw or subject the battery to sever physical shock.

— Do not directly solder the battery terminals.

— Do not attempt to disassemble or modify the battery in any way.

— Do not place the battery in a microwave oven or pressurized container.

— Do not use the battery in combination with primary batteries(such as dry-cell batteries) or batteries of different capacity, type or brand.

— Do not use the battery if it gives off an odor, generates heat, becomes discolored or deformed, or appears abnormal in any way. If the battery is in use or being recharged, remove it from the device or charger immediately and discontinue use.

Caution!

Do not use or store the battery where is exposed to extremely hot, such as under window of a car in direct sunlight in a hot day. Otherwise, the battery may be overheated. This can also reduce battery performance and/or shorten service life.

If the battery leaks and electrolyte gets in your eyes, do not rub them. Instead, rinse them with clean running water and immediately seek medical attention. If left as is, electrolyte can cause eye injury.

All our products have certificates, mainly European certificates, CE, TUV, DEKRA, etc....more