Large Hardware Factory Solar System

Large hardware factory solar system

Designing a solar system for a large hardware factory can help reduce its dependence on traditional energy sources and contribute to a more sustainable operation. Here's a general outline of the steps involved in setting up a solar system for such a factory:

1. Solar System Energy assessment:

Begin by thoroughly assessing the energy needs and consumption patterns of the hardware factory. This analysis will provide crucial information about the size and capacity of the solar system required.

2. Solar System Roof space evaluation:

Evaluate the available roof space on the factory premises to determine if it can accommodate solar panels. Consider factors like orientation, shading, and structural integrity to ensure optimal panel placement.

3. Solar System Feasibility study:

Conduct a feasibility study to evaluate the economic viability of installing a solar system. Assess the return on investment (ROI), payback period, and potential government incentives or grants that can help offset installation costs.

4. Solar system design:

Engage with solar experts or consultants to design an appropriate system that meets the energy demands of the hardware factory. Based on the energy assessment, they will determine the number of solar panels, inverters, batteries, and other components needed for the installation.

5. Solar System Permitting and approvals:

Obtain the necessary permits and approvals from local authorities and utility companies. Ensure compliance with building codes, zoning regulations, and safety standards.

6. Solar System Procurement and installation:

Source high-quality solar panels, inverters, and other equipment from trusted suppliers. Hire experienced solar installers to carry out the installation, adhering to industry best practices and safety guidelines.

7. Solar System Grid connection and net metering:

Coordinate with the local utility company to connect the solar system to the grid. Discuss options for net metering, which allows excess energy generated by the solar system to be fed back into the grid, offsetting the factory's electricity consumption during low-production periods.

8. Solar System Monitoring and maintenance:

Implement a robust monitoring system to track the performance of the solar system. Regularly inspect and maintain the panels, inverters, and batteries to ensure optimum efficiency and longevity.

9. Solar System Employee education:

Educate factory employees about the benefits and operation of the solar system. Encourage energy conservation practices and provide guidelines for efficient use of electricity in order to maximize the system's impact.

10. Solar SystemContinued optimization:

Monitor the energy consumption patterns of the hardware factory over time and consider any changes that may require adjustments or additions to the solar system. Evaluate opportunities to expand the system, incorporate energy storage solutions, or implement other renewable energy technologies.

Remember, each hardware factory's requirements may vary, so it's important to consult with renewable energy professionals to tailor the solar system design to your specific needs.

The following is the solar energy project of Enrsaver New Energy Company about the hardware factory

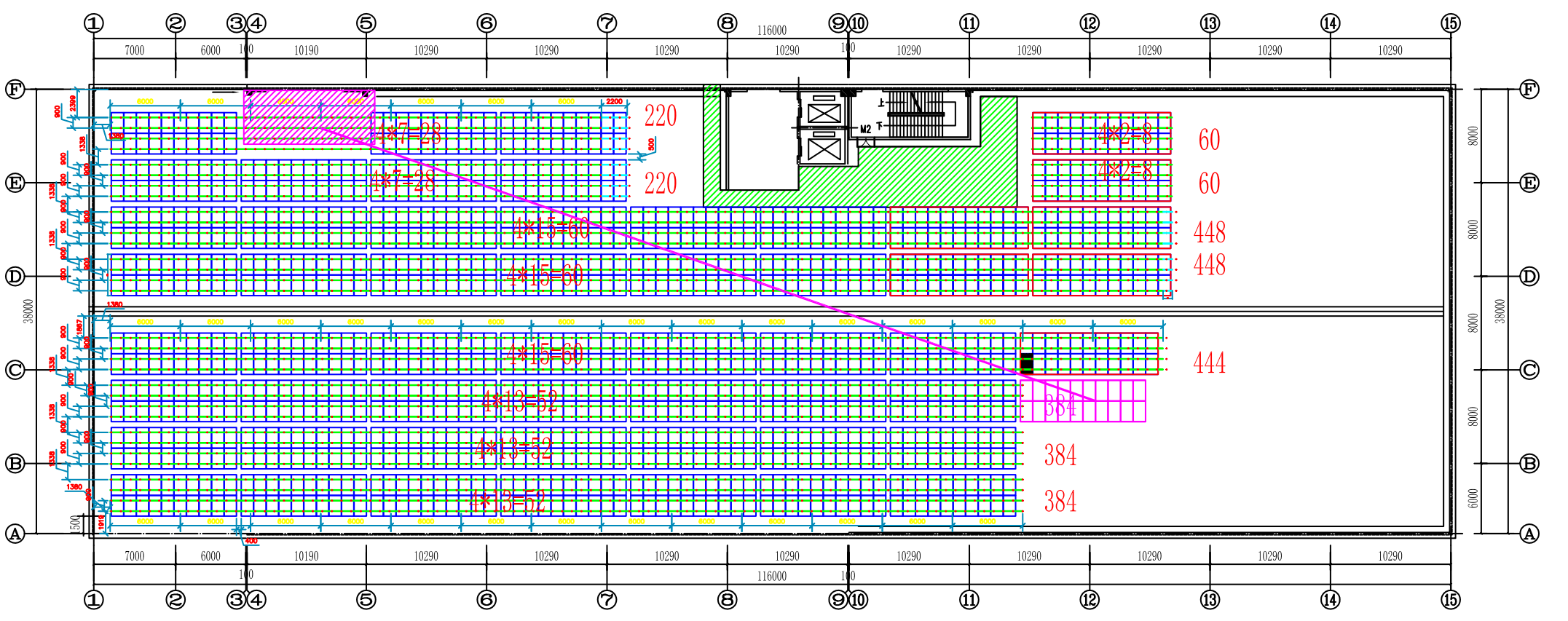

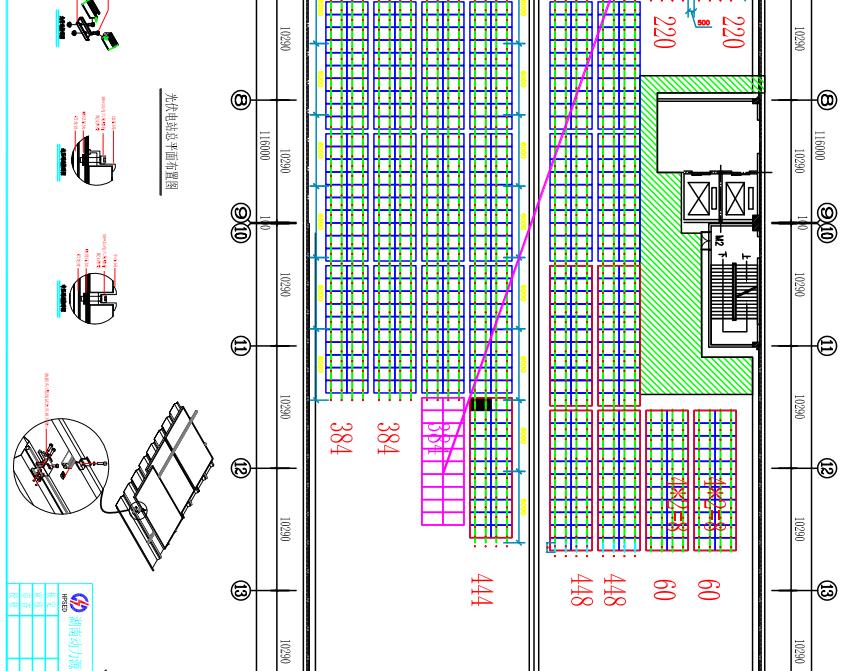

1.Project Design Drawings

|  |

|

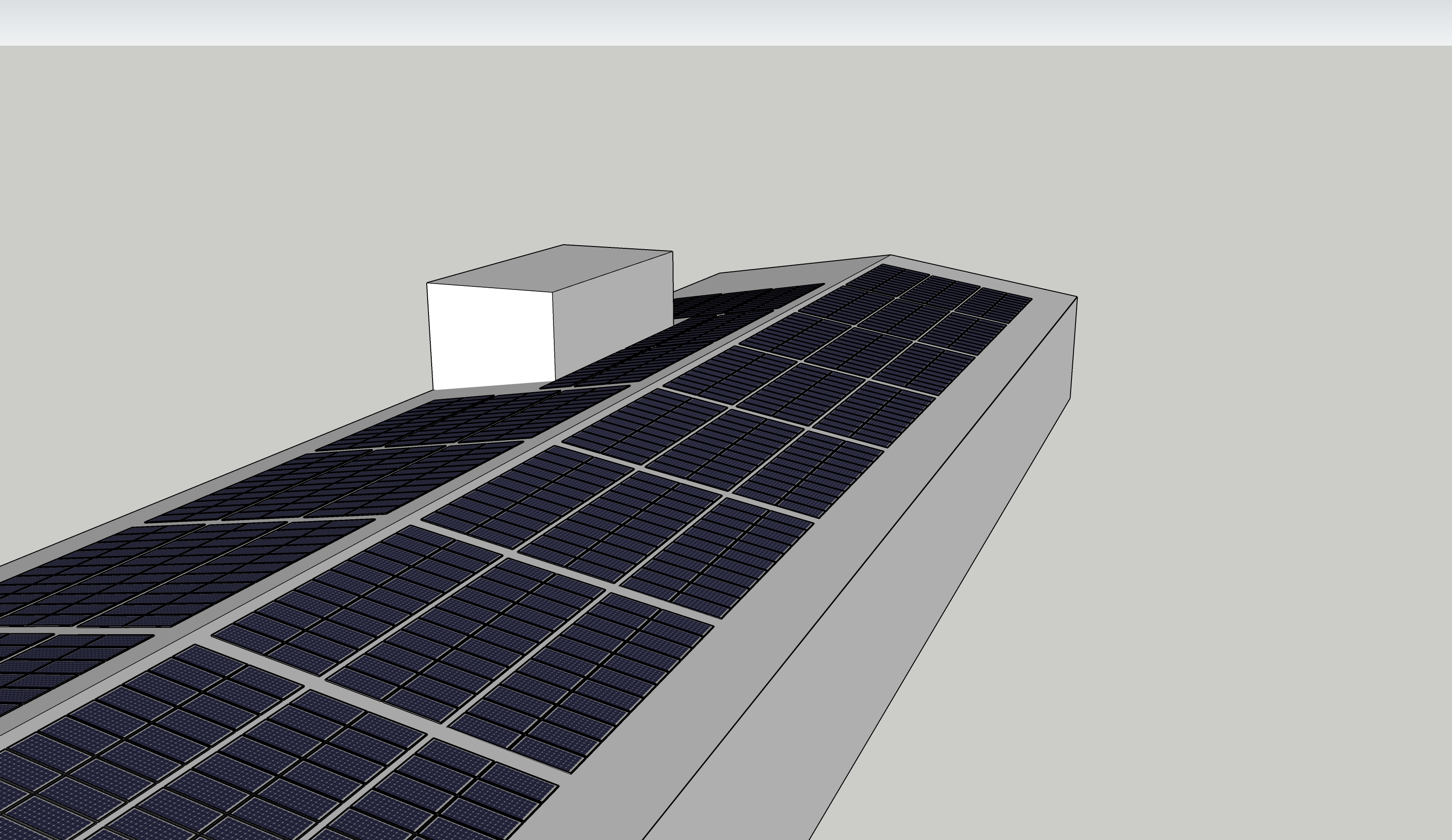

2.Real Shot

|  |

|

|

|